Advanced Manufacturing

If the global engineering and manufacturing community plans to keep unlocking the full potential of industrial 3D printing, together they will have to keep rethinking the fundamentals of design engineering and digital factories of the future. We are surrounded by 3D printing every day, and most of us have no idea. Your neighbor can walk past you with a custom 3D-printed knee replacement. The cab you take to work may have 3D-printed pulley mechanisms powering your trip. The planes we board might have a 3D-printed fuel nozzle powering the flight. The evolution of this technology is now helping power the world of manufacturing, creating new jobs, and increasing innovation across the globe. It promotes sustainability, efficiency and innovation.

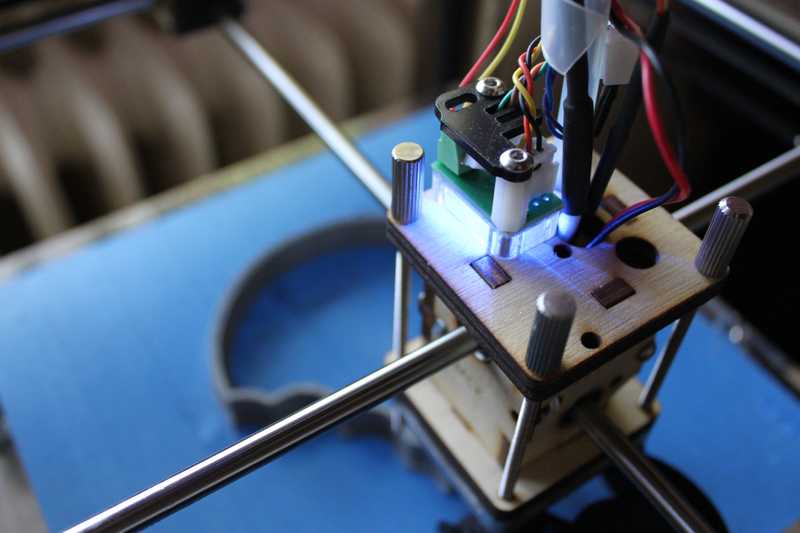

Additive manufacturing (3D Printing) is rapidly expanding the prototyping, mold/casting and real-time manufacturing capabilities of many industries. However, the quality of AM produced parts is dependent on a number of machine controls, parts geometry and process parameters in both the extruded materials (plastic or metal or multi-materials used for 3D printing) and the finished printed process itself. The variability of these parameters affects the manufacturing drastically and therefore standardized processes and fine-parameter-tuned methodologies (manufacturing know-how) need to be developed to characterize the technology for end use applications and enable the technology for the best manufacturing results.

New Thinking = New Tools

In order to maximize and understand the freedom that 3D printing allows when utilizing new materials, industrial designers, mechanical engineers, and material scientists must work in harmony from the beginning to understand new material properties. Enter iC3D, a strong culture-first organization who is a leading innovator in 3D equipment, filaments and services. “IC3D customers aren’t just buying the best products.” remarks Kimberly Gibson, CMO of iC3D “They’re buying the trust, confidence, and security that can only come from a team who designs their products for themselves first, and the market second.” In addition to developing custom 3D printing equipment, iC3D works with leading polymer companies like Dow, DuPont, and GE to develop high-quality filament for 3D printers and manufactured in in the USA. Offering 100% satisfaction and a trouble-free experience are the core components of the iC3D culture and a hallmark of their products and services.

It can be extremely intimidating for companies to rethink and rebuild their workflows and processes as it relates to engineering and manufacturing. More and more, companies are ready to embrace these new data-driven workflows but need advanced technologies to guide and automate the end-to-end data collection and analytically driven process control to ensure successful execution. The relentless pace of innovation within the additive manufacturing industry requires the use of responsive technologies, like affordable smart sensors and process controllers and flexible cloud infrastructure services (from Technicity and iotery.io).

While digital design and additive manufacturing innovation offers boundless possibilities for growth and value creation, it comes with its own set of engineering challenges. Making sense of the strategic and technical priorities is a core strength of Technicity. “Connecting our client’s discrete and process manufacturing equipment together and to the cloud was important; but making sure that their on-demand printed parts business connected seamlessly with their customers created exceptional business value and growth for iC3D,” observes BJ Yurkovich, CEO of Technicity.

The Result: an innovative and robust connected manufacturing platform that provides iC3D with real-time parameter-based controls for their high-quality filament extrusions lines, and the ability for better job control and finished product quality in their discrete parts and molds manufacturing lines. Driven by a network of process controllers and powerful and secure IoT cloud services, the iC3D Advanced Additive Manufacturing Platform provides full remote monitoring of every spool of filament and every production part. Line status, machine status, flow rates, temperatures, pressures, deposition rates, and more can be monitored, controlled and calibrated right from the cloud.

About Technicity

Technicity is a connected strategy and product engineering company. We work with you to ideate, design, prototype, launch, and then transfer your concepts and ideas. Throughout the process, we innovate with you at every step, ensuring the best possible connected products, services, or concepts that get delivered to your end-users. Our unique approach to scope definition and innovation sets the stage for success. Show others your vision by putting together a proof of concept to raise money, to prove an idea works, or to see a concept in action. We provide services to finish out the scope definition with a first production release so you can launch your connected vision to the world. Start making your connected products vision a reality today, contact us at Technicity.io.

Featured Service: iotery

Iotery is Technicity’s Internet of Things (IoT) Managed Service that removes the guesswork, cost, and burden from maintaining your own IoT cloud infrastructure. Create your networks and devices, either in the Iotery dashboard, REST API, one of our many SDKs (e.g. node.js or python). Connect your embedded device using the Embedded API or the python SDK and start sending data. Offer new IoT connectivity services to support rapidly growing customer IoT data and application needs. Service large geographic areas with security and ease. Demonstrate added value through automation, monitoring, analytics, and insights. Rapidly deploy managed environments, operations, and support for your products or clients. To learn more - or to get started in as little as 15 minutes - connect with us at Iotiery.io.

We respect the privacy of our clients. For more information on specifics and how Technicity can use its experience to help you, contact us.